Graphene’s extraordinary properties have captivated researchers for over a decade, yet many applications remain confined to laboratories due to significant challenges in functionalization. Recent research led by Chamalki Madhusha, a Ph.D. researcher at Monash University, reveals a promising solvent-free, bio-derived method for producing nitrogen-doped graphene nanoplatelets (N-GNPs), paving the way for more sustainable production processes in advanced materials.

The study, published on December 25, 2025, in ACS Sustainable Chemistry & Engineering, addresses a critical issue in graphene technology. While pristine graphene exhibits remarkable strength and conductivity, many applications, such as smart coatings and self-healing polymers, require chemical modifications to enhance dispersibility. Traditional methods for nitrogen doping often involve toxic precursors, extensive purification, and high-temperature processing, resulting in substantial environmental impacts.

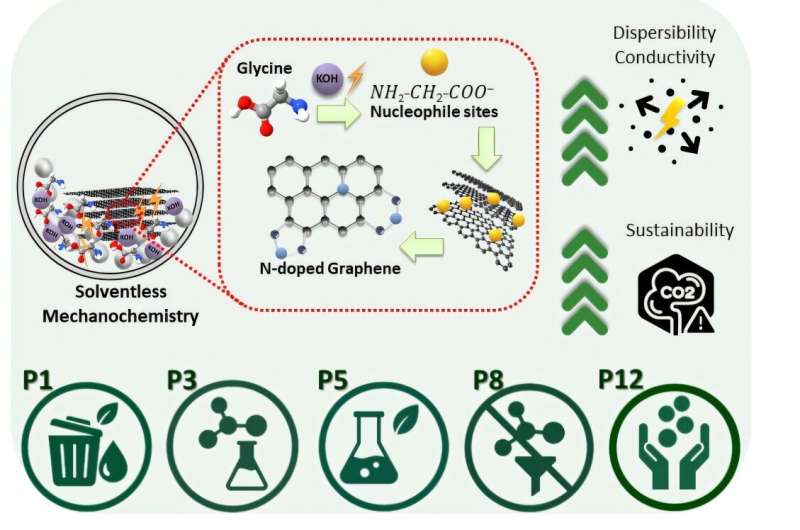

Madhusha and her colleagues turned to mechanochemistry, a technique that utilizes mechanical forces to facilitate chemical reactions without solvents. By employing a ball-milling process, researchers successfully functionalized graphite with a bio-derived nitrogen source—amino acids—under ambient conditions. This revolutionary approach eliminates the need for harsh chemicals and high-energy processes, generating nitrogen-doped graphene nanoplatelets that retain high electrical conductivity while improving dispersibility.

Assessing Sustainability Beyond Performance

In evaluating the sustainability of their method, the researchers focused not only on the material’s performance but also on the environmental implications of its production. They employed qualitative and quantitative metrics, such as the E-factor, which measures waste generated per unit of product. The new process achieved an impressive material yield of approximately 80% and significantly reduced waste generation compared to conventional methods.

This innovative approach not only cuts down energy consumption but also highlights how design choices in material production can impact sustainability. By removing solvents and post-annealing steps, the team demonstrated that advanced materials could be produced with lower environmental footprints without sacrificing performance.

The incorporation of nitrogen atoms into the graphene lattice alters electron movement, enhancing electrical conductivity and chemical reactivity. The N-GNPs produced in this study maintain high structural integrity while offering functional benefits that can improve the properties of composite systems.

Transforming Material Engineering

One of the most exciting applications of N-GNPs lies in their compatibility with vitrimers, a class of polymers that combine the durability of thermosets with the reprocessability of thermoplastics. When integrated into vitrimer matrices, nitrogen-doped graphene nanoplatelets serve as multifunctional fillers, enabling electrically triggered self-healing, enhancing mechanical properties, and improving overall conductivity.

This advancement opens up possibilities for developing repairable coatings and recyclable composites, addressing both performance and sustainability concerns in materials engineering. The implications extend beyond graphene, as the research encourages a reevaluation of how advanced materials are synthesized.

As industries in electronics, aerospace, and energy storage increasingly prioritize sustainability, the findings from Madhusha’s research underscore the potential of mechanochemical methods in reducing waste and energy usage while creating high-performance materials.

Looking ahead, the team plans to explore the adaptability of this green synthesis approach for other dopants and scalable manufacturing routes. The goal is to not only produce better materials but to innovate the processes through which they are made, aligning advances in nanomaterials with sustainability objectives.

In conclusion, this study marks a significant step toward integrating green chemistry principles into materials design. As demand for functional materials rises, sustainable synthesis strategies will play a vital role in shaping the technologies of the future.