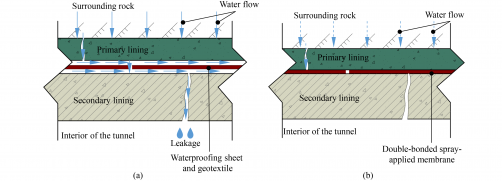

Water leakage has long plagued tunnel engineering, posing a significant threat to operational safety and structural integrity. Traditional waterproofing systems, which utilize non-bonded waterproof sheets, often fail to create a secure bond with primary and secondary linings. As a result, groundwater can flow between layers, leading to accelerated aging of the tunnel lining and potential structural failures. In a groundbreaking study, a team of researchers has proposed a novel waterproof-drainage system designed specifically for tunnels that utilize double-bonded waterproofing materials.

The research, conducted by a collaborative team including Xiaohe SUN and Chenghua SHI from Central South University, Guoqing XIAO from PowerChina ZhongNan Engineering Corporation Limited, Yangyang GE from Beijing Oriental Yuhong Waterproof Technology Co. Ltd., and Chengyong CAO from Shenzhen University, presents findings in a paper titled “A Novel Tunnel Waterproof-Drainage System Based on Double-Bonded Waterproofing Materials and Its Seepage Characteristics.” The study introduces a system that addresses the inherent limitations of traditional drainage methods in tunnels equipped with double-bonded spray membrane waterproofing materials.

Innovative Design and Key Components

The proposed system is structured around the concept of “localized drainage and pressure reduction.” Its design encompasses four essential components:

1. **Waterproof System**: This includes a double-bonded spray membrane situated between primary and secondary linings, excluding the arch section, alongside secondary lining concrete.

2. **Upper Circumferential Drainage System**: Plastic drainage sheets are placed between the membrane and primary lining, complemented by transversal guide pipes that direct groundwater towards longitudinal pipes leading to a central ditch.

3. **Bottom Circumferential Drainage System**: This consists of bottom drainage blind pipes that collect groundwater from surrounding rock, alongside vertical guide pipes that channel water into the central ditch.

4. **Longitudinal Drainage System**: It features longitudinal blind pipes, side ditches, and a central ditch, which connect the transversal drainage to facilitate the discharge of groundwater outside the tunnel.

Numerical simulations were employed to analyze the seepage characteristics of the system. The results indicate a unique distribution of water pressure within the secondary lining. Specifically, the pressure distribution takes on a circumferential “mushroom shape,” decreasing from the arch top to the tunnel bottom, and a longitudinal “wave shape,” with the lowest pressure observed at the circumferential drainage and the highest between the two drainage systems.

Performance and Applicability

Comparative tests conducted under standard conditions, specifically a water head of 160 m and rock permeability of 10−6 m/s, demonstrate that the novel system significantly reduces the maximum secondary lining water pressure to 0.6 MPa. This represents a reduction of 65% compared to fully encapsulated waterproofing systems, which exhibit a pressure of 1.7 MPa, and a 30% reduction compared to traditional drainage systems, which peak at 0.86 MPa.

Further analysis confirms that the system effectively reduces static water pressure by at least 40% across various groundwater environments. In ultra-low permeability strata, characterized by 10−7 m/s, the reduction can reach approximately 85%. The findings also highlight that bottom blind pipes are more effective in high-permeability rock, while upper drainage sheets perform better in low-permeability conditions. This adaptability enhances the system’s overall applicability.

The comprehensive research is detailed in the paper “A Novel Tunnel Waterproof-Drainage System Based on Double-Bonded Waterproofing Materials and Its Seepage Characteristics.” For further reading, the full text is available at https://doi.org/10.1007/s11709-024-1100-4.